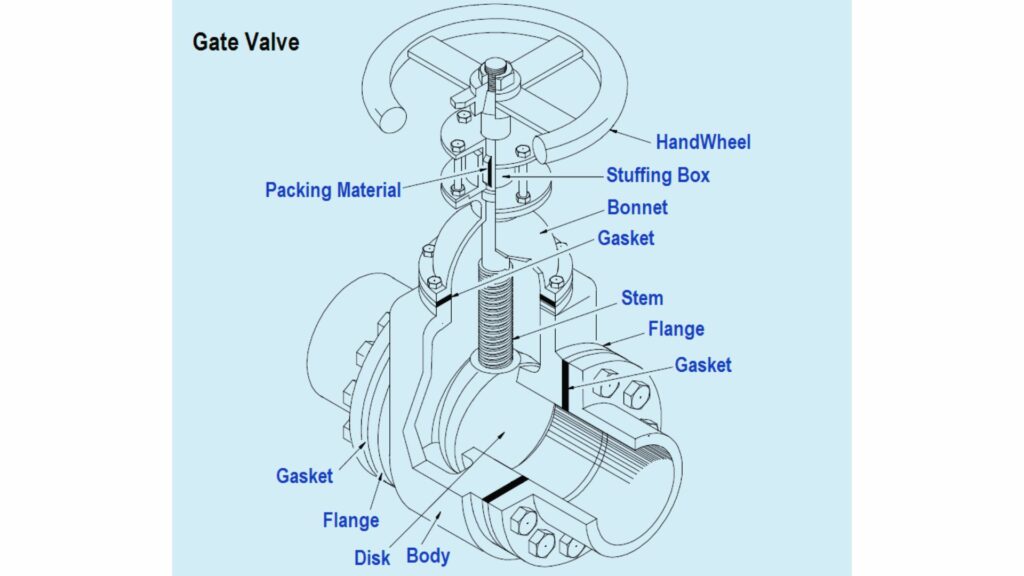

A gate valve is a type of valve that is used to regulate the flow of liquids or gases through a pipeline. It consists of a rectangular or circular gate that slides up and down within a cylindrical body to open or close the flow of fluid. The gate is typically connected to a stem that extends out of the body of the valve, and is raised or lowered using a handle or wheel.

Gate valves are commonly used in a variety of applications, including water, oil, and gas pipelines, as well as in industrial and commercial settings. They are known for their durability and ability to withstand high pressure and temperature fluctuations, and are often used in systems where a tight seal is required. However, gate valves are not suitable for use in situations where precise flow control is needed, as the gate can only be fully open or fully closed.

Table of Contents

ToggleWhat are the advantages of Gate Valve

There are several advantages to using a gate valve:

Simplicity: Gate valves are relatively simple in design and construction, which makes them easy to manufacture and maintain.

Durability: Gate valves are known for their durability and are able to withstand high pressure and temperature fluctuations. They also have a long service life and can be used for many years with proper maintenance.

Tight seal: Gate valves are able to create a tight seal when closed, which makes them suitable for use in systems where a leak-free seal is critical.

Ease of operation: Gate valves are easy to open and close, and the handle or wheel can be used to quickly stop or start the flow of fluid.

Versatility: Gate valves are available in a wide range of sizes and materials, and can be used in a variety of applications, including water, oil, and gas pipelines.

Low cost: Compared to other types of valves, gate valves are generally less expensive to purchase and maintain.

How to overhaul a Gate Valve

Overhauling a gate valve typically involves disassembling the valve, inspecting and cleaning the various components, and replacing any damaged or worn parts. Here are the general steps for overhauling a gate valve:

Shut off the valve and relieve any pressure in the system.

Close the gate fully and remove any handwheels, bonnets, or other covers.

Carefully remove the stem and gate from the valve body.

Inspect the components for damage or wear, and clean them as needed.

Replace any damaged or worn parts, such as the gate, stem, packing, or seat.

Reassemble the valve, making sure that all components are properly aligned and tightened.

Test the valve to ensure that it is functioning properly.

What are the disadvantages of Gate Valve

Some of the disadvantages of using a gate valve include:

Not suitable for precise flow control: The gate in a gate valve can only be fully open or fully closed, which means that it is not suitable for use in situations where precise flow control is needed.

Not suitable for viscous or abrasive fluids: The gate in a gate valve can become damaged or wear over time when used with viscous or abrasive fluids, which can lead to leakage or reduced performance.

Tendency to stick or freeze: The gate in a gate valve can sometimes become stuck or freeze in place, especially if the valve has not been used for an extended period of time or if it has not been properly maintained.

Higher pressure drop: When compared to other types of valves, gate valves tend to have a higher pressure drop, which means that they can cause a greater reduction in pressure as the fluid flows through the valve.

Limited flow control: The gate in a gate valve can only be fully open or fully closed, which means that it is not suitable for use in situations where fine flow control is needed.

Large size and weight: Gate valves tend to be larger and heavier than other types of valves, which can make them more difficult to install and maintain.

Different types of Gate Valve

Solid wedge gate valve: This type of gate valve has a solid wedge-shaped gate that is raised or lowered to open or close the flow of fluid. Solid wedge gate valves are suitable for use in high-pressure systems and are often used in water and gas pipelines.

Flexible wedge gate valve: This type of gate valve has a flexible wedge-shaped gate that is raised or lowered to open or close the flow of fluid. The flexible wedge is designed to conform to the shape of the valve seat, which helps to create a tight seal when the valve is closed. Flexible wedge gate valves are suitable for use in high-pressure systems and are often used in water and gas pipelines.

Parallel slide gate valve: This type of gate valve has a gate that slides parallel to the flow of fluid in order to open or close the valve. Parallel slide gate valves are suitable for use in systems with low- to medium-pressure and are often used in water and sewage pipelines.

Knife gate valve: This type of gate valve has a gate that is shaped like a blade or knife, and it is raised or lowered to open or close the flow of fluid. Knife gate valves are suitable for use in systems with low- to medium-pressure and are often used in water and sewage pipelines.

Sluice gate valve: This type of gate valve has a gate that is mounted on a pivot, and it is raised or lowered to open or close the flow of fluid. Sluice gate valves are suitable for use in systems with low- to medium-pressure and are often used in water and sewage pipelines.