Before overhauling any centrifugal pump first start a standby pump and then stop the pump which we are going to overhaul. After that close the discharge valve and suction valve of the pump. Open the vent and cross-check whether the valve is holding or not. Trip the breaker and lockout & tag out respectively.

Let us start to dismantle the pump step by step –

- Mark the points on coupling and casing with any suitable marker.

- Then remove the distant piece fitted between motor and pump coupling after removing both motors and pump side fixed coupling bolts and disc.

- Remove the motor with the help of a chain block and secure it separately and apply insulation tape on its wires providing extra protection to them.

- Disconnect the cooling connections to the mechanical seal.

- And then finally remove the casing of the top cover bolts.

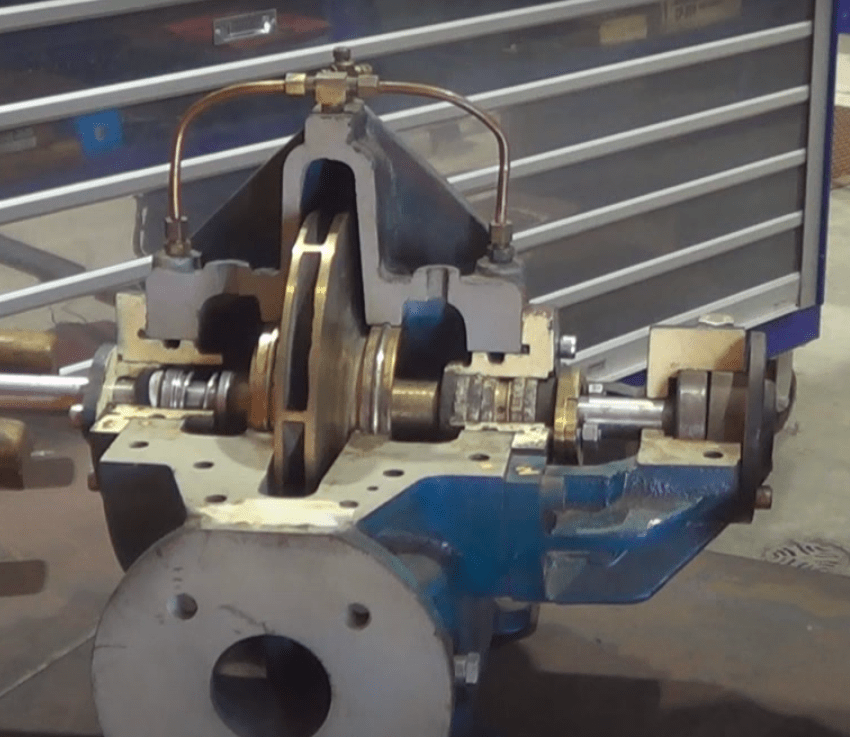

- Once the casing cover topmost bolts are removed, the pump assembly is open to remove from place alongside with shaft, bearing housing, bearing, impeller, impeller shaft with sleeve and mechanical seal.

- Then finally the slacken the impeller lock nut and remove the impeller from the shaft.

- We can easily remove the shaft key after that and also the distance ring.

- Slacken the holding screw and remove the mechanical seal rotating part.

- Loosen the bearing housing bolt fitted on the casing cover.

- Remove the casing cover from the shaft.

- And also remove the shaft sleeve from the shaft.

- Finally, remove the bearing housing cover and bearing retaining circlip

- Now with the help of the bearing puller, remove the bearing from the bearing housing.

Note;- If the bearing is gone then replace it with a new one. Put the new bearing in Lube oil to heat it and again put back in the shaft and slowly tap it to fit it properly in the pump shaft.

There are two types of seals provided in centrifugal pump

What checks to be done during overhauling of centrifugal pump

- Check the condition of the shaft as sometimes it gets bend and hence check it by putting it on lathe machine to check the shaft trueness.

- Check impeller for pitting, erosion or corrosion. If found then rectify it with brass putty and if not possible then replace it with a new one

- Clearly see the shaft sleeve for any groove or pitting.

- Check the wear ring clearance and replace it if exceeds the set limit

- Inspect the shaft key and slot and also the coupling conditions.