Before explaining the working of FWG here are some points one should know .

The boiling point of water can be reduced by reducing the surrounding atmospheric pressure and by maintaining it at low pressure, water can be boiled at a low temperature of about 80˚ C. The main source of heat for boiling seawater is main engine jacket cooling water which has absorbed the heat of the main diesel engine of the ship

Table of Contents

ToggleWorking of Fresh Water Generator

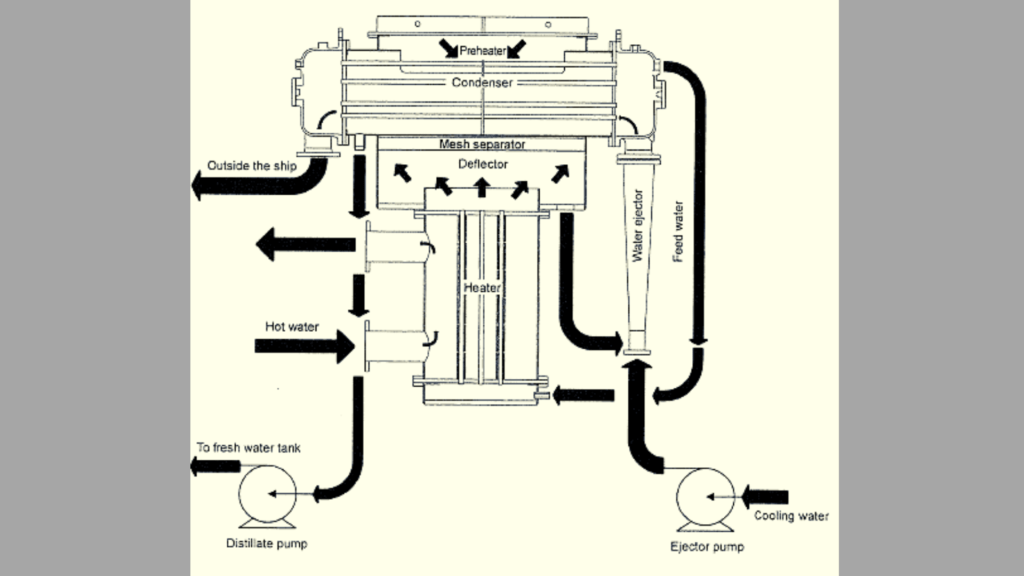

The inside of the generator is always kept at a high vacuum by means of a water ejector. The seawater fed by the ejector pump drives the water ejector.

Due to the low pressure in the chamber Seawater boils off and get converted to steam. From the generated vapour, seawater mist is separated by the deflector and mesh separator and the vapour enters into the condenser.

Note:- The seawater mist with the remaining brine which has not been evaporated is discharged overboard by the brine ejector.

The vapour generated enters into the condenser where it is condensed into distillate by the seawater flowing into the tubes of the condenser. When the vapour gets condensed it gets converted into the distillate.

The salinity of the distillate is continuously monitored with the salinity indicator and it prevents the high salinity water from flowing into freshwater tanks.

What are the Safety Equipments in Fresh Water Generator

- Vacuum Breaker – It is used to release vacuum when we shut down the freshwater generator.

- Relief Valve – It is used to relieve excess pressure.

- High Salinity Alarm– It is fitted to a salinometer and when the salinity of Freshwater increases it sounds the alarm.

- Temperature Gauge – By throttling the Bypass valve. we are adjusting shell temperature by adjusting quantity flow. If seawater temperature increases low capacity of freshwater production