In any tanker ship, purging and gas freeing are the most critical steps to be done for safe cargo operations. These are very critical operations and should be done very carefully with all proper guidelines.

When the inert gas is inserted into a tank which is already in an inerted condition, it further reduces the oxygen content or reduces the hydrocarbon gases present in it to a level at which it is unable to support combustion and reach flammable free zone .

Table of Contents

ToggleWhat is Purging and Why it is done ?

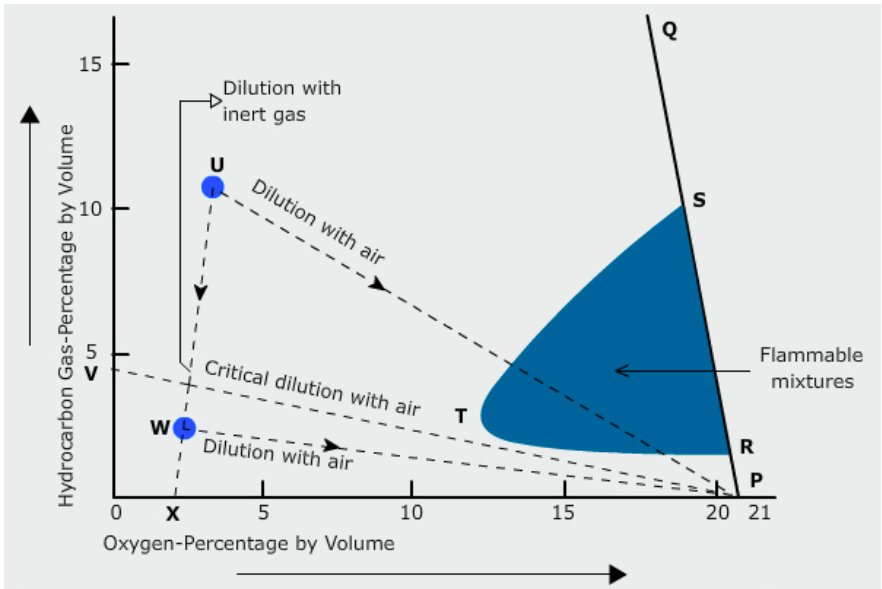

On oil tankers before gas freeing, it is desirable to reduce the hydrocarbon content to 2% or less by volume, this is done by purging (replacing tank atmosphere) with inert gas. Purging is done so that during gas freeing, the atmosphere in the tank is never in the flammable range, i.e. the amount of hydrocarbon content is always below 5% by volume (critical level for ignition of hydrocarbon vapour, provided volume of Oxygen is greater than 11% by volume).

There are two methods to do purging in tankers. They are –

- Dilution Method

- Displacement Method

Dilution Method –

In the dilution method the incoming inert gas mixes with the original tank atmosphere to form a homogeneous mixture throughout the tank so that, as the process continues, the concentration of the original gas decreases progressively and continues until the hydrocarbon content is below 2% (checked with a tank scope). In this method normally one tank is inerted at a time.

Displacement Method –

In the displacement method, the inert gas enters from the top of the tank, and the heavier hydrocarbon gas exits through the tank bottom through suitable piping. When using this method it is important that the inert gas has a very low entry velocity so that the interface between the hydrocarbon gas and the inert gas is stable (to prevent mixing). In this method, several tanks can be inerted and purged at the same time.

NOTE :

- When doing inerting and purging, the Oxygen and gas concentrations must be checked regularly at different tank levels to check operation efficiency.

- One must also take normal safety precautions when venting the mixture of inert gas and petroleum gas to the atmosphere during the purging process as this mixture can become flammable when mixed with air.

What is Gas Freeing and its use ?

The gas freeing operation on oil tankers is considered to be one of the most hazardous operation. Every stage of the gas freeing operation poses a unique hazard.The toxic effect of petroleum gas poses additional risk to the personnel involved. A careful planning is required for the operation. Some of the measures that should be taken are –

- The ISGOTT publication should be referred to identify and control the hazards involved.

- The Chief Officer is in charge of the gas freeing operations and he shall ensure that all crew involved are well briefed in detail about every step.

- Some tank openings may have to be left open during the gas freeing and such openings should be well guarded to prevent accidents. Only the personnel directly involved in the operation should be allowed to be on the deck.

- Proper PPE must be worn by all crew involved. All electronic equipment used must be of an intrinsically safe type.

- The crew on any small craft which is alongside during the operation should be notified. The atmosphere surrounding the area where the operation is done should be monitored for hydrocarbon vapours , as it can form a combustible mixture with air.

- The composition of the atmosphere in the tank, pipe or any other space, should not be allowed to enter the flammable range during the gas freeing operation.

- Hydrocarbon gas is heavier than air. Any hydrocarbon vented can hover on the deck if the venting velocity is less. The crew working in these areas must be in constant vigil for the presence of toxic vapours.

- Large amounts of hydrocarbon gas are likely to be released especially in the initial stages of the operation.

- Approved methods must be adopted when venting flammable gas into the atmosphere. If the gas is to be vented close to deck level, the openings must be limited to achieve a good venting velocity.

- The IG inlet to the tank should be isolated using a flange once the desired oxygen and LEL levels are achieved. Throughout the operation, precautions must be taken so that any vented gas or inert gas does not reach the accommodation. It may be necessary to change course depending on the wind direction.

- A positive pressure is to be maintained within the accommodation and air condition intakes should be operated in recirculation mode