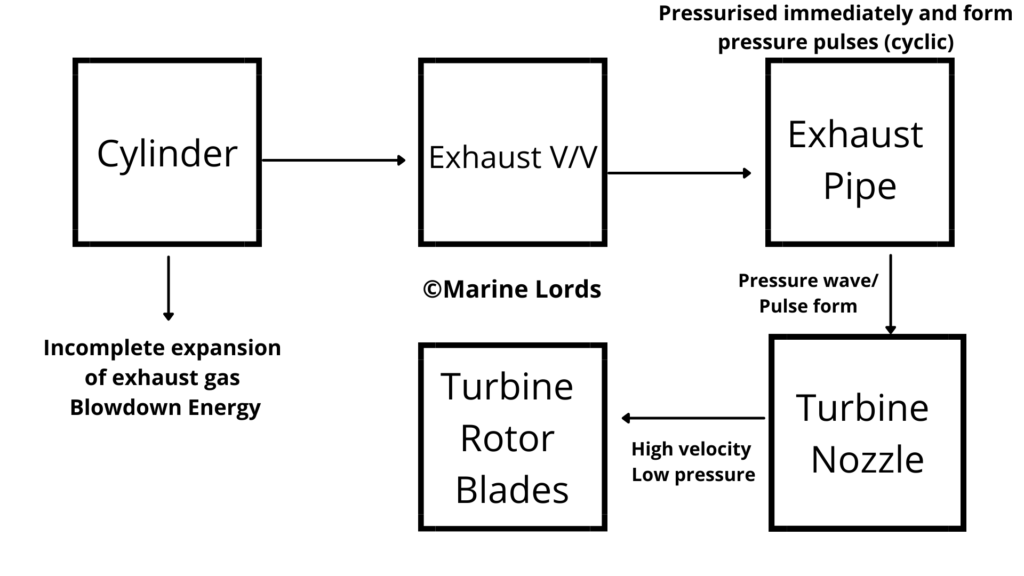

- In Pulse-type Turbocharging system, it makes full use of the high pressure and temperature of the exhaust gas during the blowdown period and rapidly opening of the exhaust valve.

- The Exhaust gas reaches the cylinder at extreme velocity as pressure energy is transformed into kinetic energy to form a pressure wave or pulse in the exhaust Pipe and it eventually lead to the turbocharger turbine.

- The exhaust pipe so constructed in small diameter is quickly pressurized and boosted up to form pressure pulses or waves.

- The Pressure wave reached to turbine nozzle and further expansion takes place.

- Some interference may exist between exhausting and scavenging among cylinders.

- The exhaust pipes are grouped or tuned such as to prevent any possibility of exhaust going into another cylinder during the scavenging period.

- The pipes are organised in lesser diameter to increase up pressure pulses and used in little lengths that are straight to prevent energy losses.

- No sharp bends in the pipe are provided, and neither is any obstruction on the exhaust pulse flow.

- The number of exhaust branches depends on a firing order, number of cylinders and turbocharger design.

Table of Contents

ToggleAdvantages of Pulse-type Turbocharging system

- At reduced load and reduced speed, more efficiency can be seen.

- At a low load, it does not require any form of scavenging assistance.

- During load change, good turbocharger acceleration and response is there.

- High energy is available at the turbine inlet.

- The system does not require a larger volume to accommodate the exhaust pipe inside as it does not require a large diameter manifold.

Disadvantages of Pulse-Type Turbocharging system

- The exhaust grouping is complicated and quite complex in design.

- Very unique sizes of exhaust pipes are required for spare.

- Pressure wave reflection problems may be caused in some engines.

- Poor Turbine efficiency at a very high rating

- Firing order, number of cylinders, number of turbochargers must be considered during exhaust grouping.